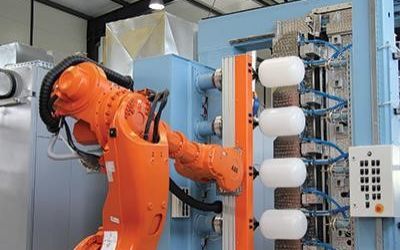

Assembly Line Filling Stations

Application Overview:

The world of automation is growing at an exponential rate. Filling stations now run un-manned and must deliver the exact same volume of fluid. In many cases, the supply line pressures can vary dramatically due to production demands. An increase in pressure can cause overfill situation – a decrease in pressure may cause an underfill. Neither is acceptable.

Kates Solution:

By cycling the Kates Flow Rate Controller for a known amount of time, filling stations will always fill to the desired volume. Regardless of pressure fluctuations in the supply lines, a 10 gpm setting for 6 seconds will always yield 1 gallon of fluid. Even being subjected to the severe water hammer of this type of application, the Kates controller will work well for decades under these conditions.