How the Kates Valve Benefits Blending & Batching Systems

We are often asked if Custom Valve Concepts Kates Flow Rate Controller would benefit blending & batching systems, and the answer is yes! Blending & batching systems require pressure to remain constant so that the system does not get disrupted. The Kates design is self-contained and will be a cost-effective addition to your system.

What are batching and blending systems?

In process systems the term blending usually is a combination of several process fluid lines which merge into a single output stream. Normally this is a continuous process in a closed piping system. Batching is the collection of various process materials into a vessel(s.) Batch processes have a beginning and an end. Often, batches are sequential and do not necessarily generate an end product. Batching and blending would normally involve some type of mixing action in the process, to create a uniform distribution of each component.

What industries utilize batching and blending systems?

Most process industries utilize batching or blending or both. Some examples are beverage processing, biotech products manufacturing, dairy processing, food processing, pharmaceutical formulations and soap manufacturing. Refineries utilize storage tanks and reactor vessels for de-fatting, bleaching, deodorization, cooling and dewaxing and hydrocracking. Chemical plants and the waste treatment industry utilize batching and blending in many processes; formulations, dilution and dosing are prevalent applications.

What challenges/problems might these applications face?

The first challenge of batching or blending operations is to deliver the materials in the proper amounts/ratios. Once the correct amounts are accomplished, some materials and combinations of materials will blend in almost any blender, producing a consistent, uniform mixture. Other material combinations are sensitive to a variety of atmospheric influences or to particle size variations, densities, frictions, cohesions, permeability, compressibility or chemical composition. They will either mix poorly initially or eventually demix or segregate in subsequent handling steps, with the flow properties of materials also being a consideration.

Some blending systems use simple mechanical devices while other processes demand more integrated controls and monitoring.

Some systems use centrifugal pumps to perform volumetric metering tasks that would otherwise require piston or diaphragm pumps. The high reliability and low cost of centrifugal pump-based flow metering systems often make these a better choice than traditional positive displacement pumps for the blending systems.

Batching is like a perpetual start up and shutdown. Equipment is continually coming into and out of service in batch operations. Target operating conditions must be reached. As soon as these are reached, the operation moves on to the next task possibly using different equipment and different measurements and valves as quickly and as repeatable as possible.

What is Kates solution?

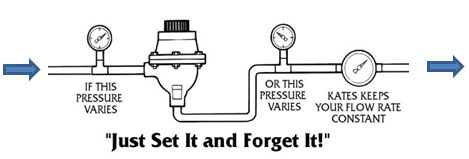

Kates is a fully automatic flow rate controller that provides set flow rates regardless of pressure surges that are inherent in most batching and blending systems. Pressure changes are typically a major factor in disrupting a balanced system. Kates is fully mechanical, self-contained and does not require any outside signals other than setting the desired flow.

The Kates design has several advantages beyond pressure compensation to maintain flow. A set point accuracy of 1.5% is combined with an extremely fast response time of 1-2 seconds. This allows for on/off batching operations to be optimized.

Kates when used in tandem with a centrifugal pump provides accurate flow control while maintaining cost effective.

Sign up to receive the CVC Engineering Insights in Your Inbox:

Join us on Social Media!

Learn more about Custom Valve Concepts

Blog categories

- mechanical design (7)

- General (15)

- history (1)

- quality (4)

- manufacturing (4)

- meet the team (4)

- FAQ Kates (3)